A manual transaxle is a component that combines a manual transmission and differential, essential for transmitting power to wheels in vehicles. Understanding its functionality and components is crucial for diagnostics and maintenance, as detailed in diagrams.

1.1 Definition of Manual Transaxle

A manual transaxle is a self-contained component that integrates a manual transmission system with a differential, designed to transmit power from the engine to the vehicle’s wheels. It is commonly used in vehicles with front-wheel drive (FWD), rear-wheel drive (RWD), or all-wheel drive (AWD) configurations. The transaxle housing encases the gearbox, differential, and other essential components, ensuring efficient power distribution and gear shifting. This design simplifies the drivetrain layout and reduces the overall weight of the vehicle. Understanding the manual transaxle is crucial for diagnosing issues and performing maintenance, as its complexity requires precise synchronization of gears, bearings, and seals. Proper functioning ensures smooth acceleration, optimal fuel efficiency, and minimal wear on drivetrain components.

1.2 Purpose and Function in Vehicles

The primary purpose of a manual transaxle is to transmit and distribute engine power to the wheels efficiently. It serves as the core of the drivetrain, enabling vehicles to accelerate, decelerate, and maintain speed smoothly. The transaxle’s function involves altering gear ratios through manual shifting, allowing drivers to optimize engine performance for varying driving conditions. Additionally, it incorporates a differential to enable wheels to rotate at different speeds during cornering, enhancing traction and stability. By integrating transmission and differential into a single unit, the manual transaxle reduces mechanical complexity and improves overall vehicle responsiveness. Regular maintenance, such as fluid checks and seal inspections, is essential to ensure its longevity and performance. A well-functioning transaxle is vital for both fuel efficiency and driver control, making it a critical component in modern vehicle design.

Components of a Manual Transaxle

A manual transaxle consists of gears, clutch, driveshaft, CV joints, differential, and axles, working together to transmit power and facilitate smooth vehicle operation.

2.1 Gears and Gearbox

The gears and gearbox are central to a manual transaxle, enabling speed and torque adjustments. The gearbox houses various gear sets, including spur gears, helical gears, and a reverse gear. These gears are synchronized to ensure smooth shifting. The gearbox is designed to withstand stress, with bearings supporting gear shafts. Different gear ratios allow vehicles to optimize performance at various speeds. Wear on gears can lead to noise and poor shifting, emphasizing the need for proper lubrication. The gearbox also contains the synchromesh mechanism, which facilitates gear engagement. Understanding gear and gearbox operation is vital for diagnosing issues and maintaining efficiency. Regular inspection and lubrication are key to extending component lifespan.

2.2 Clutch and Pressure Plate

The clutch and pressure plate are critical components in a manual transaxle system. The clutch facilitates smooth engagement and disengagement of engine power to the transmission. When the driver presses the clutch pedal, the pressure plate releases its grip on the clutch disc, disconnecting the engine from the gearbox. This allows for shifting gears without grinding. The pressure plate applies constant force to maintain contact when the clutch is engaged. Over time, wear on the clutch facings can lead to slippage and reduced performance. Proper alignment and adjustment of the clutch system are essential to prevent premature wear. Lubrication of the clutch bearing and regular inspection ensure optimal functionality. Understanding the clutch and pressure plate’s operation is key for diagnosing issues like difficulty in shifting gears or clutch slippage.

2.3 Driveshaft and CV Joints

The driveshaft is a critical component in a manual transaxle system, responsible for transmitting power from the gearbox to the differential. It rotates at engine speed, connecting the transaxle to the wheels. Constant Velocity (CV) joints are integral to the driveshaft, enabling smooth power delivery while accommodating suspension movement and steering angles. These joints are particularly important in front-wheel-drive (FWD) and all-wheel-drive (AWD) vehicles, where the driveshaft must articulate without compromising torque transfer. Over time, CV joints can wear out due to stress and lack of lubrication, leading to vibrations or clicking noises during operation. Regular inspection and greasing of CV joints are essential to ensure long-term reliability. Understanding the driveshaft and CV joints is vital for diagnosing issues related to power delivery and drivetrain noise.

2.4 Differential and Axles

The differential is a key component of the manual transaxle, allowing the wheels to rotate at different speeds during cornering. It houses the gears that split power between the two axles, ensuring smooth traction. The axles, connected to the wheels, transfer torque directly from the differential. In FWD systems, the transaxle integrates the differential and gearbox, simplifying design. RWD systems use a separate differential at the rear. AWD systems often feature multiple differentials for enhanced traction. Wear on the differential can cause vibration or noise, while axle damage may lead to loss of power delivery. Regular maintenance, including fluid checks and sealing inspections, is crucial to prevent premature wear. Understanding the differential and axles is essential for diagnosing and repairing drivetrain issues in manual transaxle systems.

Types of Manual Transaxles

Manual transaxles vary by drivetrain type, including front-wheel drive (FWD), rear-wheel drive (RWD), all-wheel drive (AWD), and high-performance designs, each optimized for specific vehicle applications and driving conditions.

3.1 Front-Wheel Drive (FWD) Transaxles

Front-wheel drive (FWD) transaxles are designed to transmit power to the front wheels of a vehicle. They combine the transmission and differential into a single unit, reducing weight and improving efficiency. FWD transaxles are commonly found in compact and economy vehicles due to their space-saving design. The transaxle housing contains gears, bearings, and shafts that work together to deliver power from the engine to the front wheels. This configuration eliminates the need for a separate driveshaft, simplifying the drivetrain. FWD transaxles are known for their compactness and fuel efficiency, making them ideal for urban and low-performance applications. They also provide better traction in certain driving conditions, such as snow or rain, by directing power to the steered wheels. Understanding the diagram of an FWD transaxle helps in identifying key components and their roles in power transmission.

3.2 Rear-Wheel Drive (RWD) Transaxles

Rear-wheel drive (RWD) transaxles are engineered to deliver power to the rear wheels, offering precise control and superior performance. Unlike FWD systems, RWD transaxles separate the transmission and differential, often connected by a driveshaft. This setup is common in performance vehicles, trucks, and older models. The transaxle in RWD configurations typically houses the gears, bearings, and shafts responsible for torque distribution. The driveshaft transfers power from the transmission to the differential, which then splits it between the rear wheels. RWD transaxles are favored for their handling characteristics and towing capabilities. Diagrams of RWD transaxles highlight the driveshaft, universal joints, and the differential assembly, essential for understanding power flow and component interaction. This design is preferred in applications requiring high performance, stability, and durability, making it a staple in automotive engineering.

3.3 All-Wheel Drive (AWD) Transaxles

All-wheel drive (AWD) transaxles are sophisticated systems designed to distribute power to all four wheels, enhancing traction and stability in various driving conditions. Unlike RWD or FWD systems, AWD transaxles incorporate additional components such as transfer cases and center differentials. These components ensure that torque is dynamically allocated between the front and rear axles, optimizing grip and control; The transaxle in AWD configurations often includes electronic controls to monitor wheel speed and torque demand, enabling real-time adjustments. Diagrams of AWD transaxles reveal a complex interplay of gears, sensors, and actuators, illustrating how power is seamlessly transferred between axles. This technology is particularly advantageous in off-road scenarios and inclement weather, providing drivers with improved safety and vehicle command. Modern AWD systems are increasingly integrated with advanced driver-assistance technologies, further enhancing their functionality and efficiency.

3.4 High-Performance and Specialty Transaxles

High-performance and specialty transaxles are engineered for exceptional power delivery, durability, and precision, catering to niche applications such as racing, off-road vehicles, and luxury sports cars. These transaxles often feature lightweight materials, such as aluminum or carbon fiber, to reduce weight and enhance efficiency. They are designed with unique gear ratios and advanced lubrication systems to handle high torque and RPM demands. Specialty transaxles may incorporate features like limited-slip differentials or locking mechanisms for improved traction in specific conditions. Diagrams of these systems highlight their intricate design, showcasing components like reinforced gears, high-strength bearings, and specialized cooling systems; These transaxles are typically customized for specific vehicles or racing series, ensuring optimal performance in extreme environments. Their complexity and precision make them a critical component in high-stakes automotive applications.

Understanding Manual Transaxle Diagrams

Manual transaxle diagrams visually represent components, simplifying complex systems and aiding in repairs and maintenance by clearly showing how parts interact and power flows through the system.

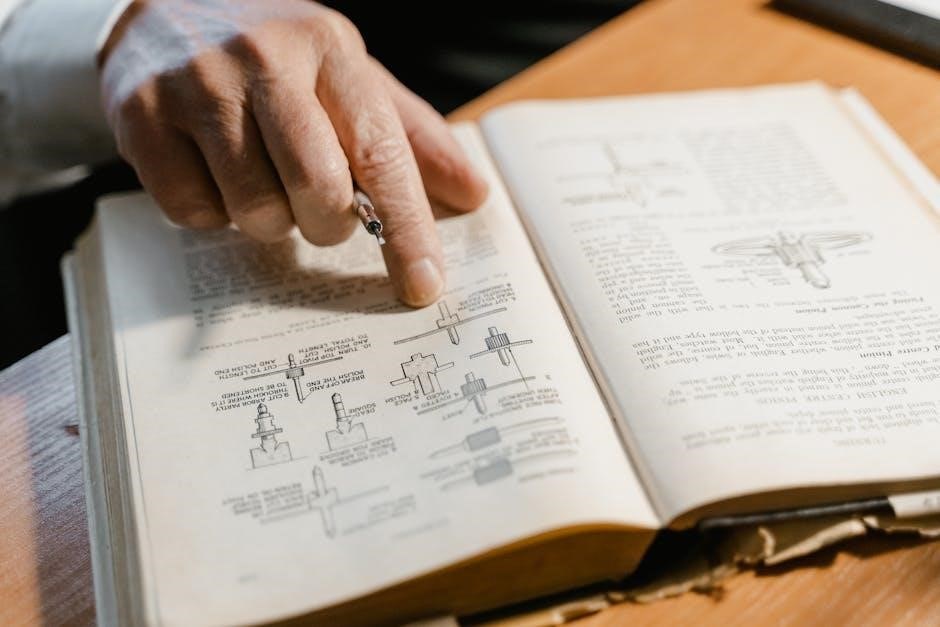

4.1 Symbols and Notations Used

Manual transaxle diagrams utilize specific symbols and notations to represent components and their interactions. These symbols are standardized to ensure clarity and consistency, making it easier for technicians to interpret the diagrams. Common symbols include geometric shapes for gears, lines for shafts, and arrows to indicate power flow. Notations often include labels for key components like bearings, seals, and sensors. Color coding or line types may also be used to differentiate between mechanical, hydraulic, or electronic systems. Understanding these symbols is crucial for diagnosing issues, performing repairs, and maintaining the transaxle. The diagrams often include a legend or key to explain the symbols, ensuring that even those unfamiliar with the system can follow the flow of power and identify potential problem areas effectively.

4.2 Identifying Key Components

Manual transaxle diagrams are designed to clearly illustrate the system’s key components, enabling technicians and enthusiasts to understand its structure and operation. The diagrams typically highlight essential parts such as gears, bearings, the clutch assembly, driveshaft, CV joints, and differential. Each component is represented with specific symbols or detailed illustrations, making it easier to locate and identify them. The gearbox, for instance, is often depicted with gears and shafts, while the differential is shown with its axles and housing. By studying the diagram, users can trace the flow of power through the system, from the clutch to the wheels. This visual representation is invaluable for diagnostics, repairs, and maintenance, as it provides a clear roadmap of how the transaxle functions and interconnects. Accurate identification of components is the first step in troubleshooting or servicing the system effectively.

4.3 Interpreting Flowcharts and Schematics

Manual transaxle diagrams often include flowcharts and schematics to visually represent the system’s operation and power flow. These diagrams use standardized symbols and color coding to depict components and their relationships. Flowcharts may illustrate gear ratios, shift patterns, and torque distribution, while schematics provide a detailed layout of mechanical and hydraulic connections. By interpreting these visuals, technicians can trace the path of power from the engine to the wheels, identifying how gears engage and disengage. Schematics also highlight fluid flow in hydraulic systems, aiding in diagnosing issues like low pressure or leaks. Understanding these diagrams requires familiarity with industry-standard symbols and notations, making them an essential tool for repairs, maintenance, and performance optimization. They simplify complex systems, enabling users to pinpoint faults and plan interventions effectively.

Maintenance and Service

Regular fluid checks, filter replacements, and inspections of gaskets and bearings are essential for optimal transaxle performance. Proper maintenance ensures smooth operation and prevents premature wear.

5.1 Fluid and Filter Replacement

Regular fluid and filter replacement is vital for maintaining the health of a manual transaxle. The transmission fluid lubricates gears and bearings, preventing overheating and wear. Old or degraded fluid can lead to poor performance, such as difficulty shifting gears or noisy operation. It is recommended to replace the fluid every 30,000 to 60,000 miles, depending on the manufacturer’s specifications. Additionally, the filter should be replaced at the same time to ensure clean fluid circulates through the system. Proper disposal of used fluid and filters is also important for environmental safety. Always consult the vehicle’s manual or a professional mechanic for specific guidance tailored to your transaxle type.

5.2 Inspecting Seals and Bearings

Inspecting the seals and bearings in a manual transaxle is essential to ensure proper function and prevent damage. Seals are critical for maintaining fluid integrity, while bearings support moving parts and reduce friction. Over time, seals may crack or wear, leading to leaks, while bearings can become worn or pitted, causing noise and vibration. Regular inspection involves checking for signs of damage, wear, or contamination. Use a manual transaxle diagram to locate these components and assess their condition. If any issues are found, such as excessive play in the bearings or fluid seepage from seals, immediate attention is required to avoid further damage. Replacement of faulty seals or bearings should be done promptly to maintain the transaxle’s performance and longevity.

Troubleshooting Common Issues

Identifying and addressing common issues in a manual transaxle, such as leaks or noisy operation, requires a systematic approach using diagrams to locate components and diagnose problems effectively.

6.1 Diagnosing Leaks and Low Fluid Levels

Diagnosing leaks and low fluid levels in a manual transaxle begins with a visual inspection of the system. Use the diagram to locate potential leak sources, such as seals, gaskets, or damaged lines. Check the fluid level by referring to the dipstick or filler plug, ensuring it matches the recommended level. Low fluid levels can cause poor performance, while leaks may lead to contamination or damage. Inspect the gearbox, differential, and driveshaft for signs of fluid leakage. Common causes include worn seals, loose connections, or damaged components. Addressing these issues promptly prevents further damage and ensures optimal functionality. Always consult the manual transaxle diagram for precise locations of components and fluid reservoirs to streamline the diagnostic process and repair.

6.2 Addressing Noisy Operation

Noisy operation in a manual transaxle can indicate underlying issues such as worn gears, bearings, or insufficient lubrication. Use the diagram to identify components like the gearbox, differential, and driveshaft, which are common sources of noise. Start by checking the fluid level, as low fluid can cause excessive wear and noise. Inspect gears for teeth wear or misalignment, and bearings for damage or play. Replacing worn parts and ensuring proper lubrication can resolve the issue. Consult the diagram to locate these components precisely. If noise persists, it may signal a need for professional inspection. Regular maintenance, such as fluid changes and component inspections, can prevent noisy operation and extend the transaxle’s lifespan. Always refer to the manual transaxle diagram for guidance on diagnosing and addressing noise-related problems effectively.

6.3 Resolving Difficulty in Shifting Gears

Difficulty in shifting gears can stem from issues like worn synchronizers, misaligned gear teeth, or insufficient lubrication. Use the manual transaxle diagram to locate the gearbox and clutch components. Inspect the clutch for proper engagement and check the gear selector mechanism for smooth operation. Lubricate moving parts and ensure gears are properly aligned. If problems persist, replacing worn synchronizers or adjusting the gear linkage may be necessary. Refer to the diagram to identify these components accurately. Regular maintenance, such as checking fluid levels and inspecting for wear, can prevent shifting difficulties. Addressing these issues promptly ensures smooth gear transitions and extends the transaxle’s lifespan. Always consult the manual transaxle diagram for precise guidance on resolving gear-shifting problems effectively.